OEM/ODM Factory Nylon Taffeta Fabric - High Density Polyethylene (HDPE) – Shielday Detail:

High density polyethylene (HDPE) softening point for 125 ~ 135 ℃,

working temperature 100 ℃;

Material features:

Heat & cold resistance, good abrasion resistance, high tensile strength, electrical insulation, good chemical stability, chemical corrosion resistance; low water absorption and permeability.

Wire by increasing HDPE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various applications:

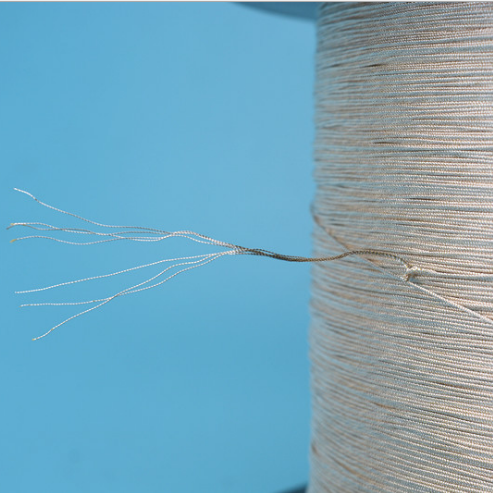

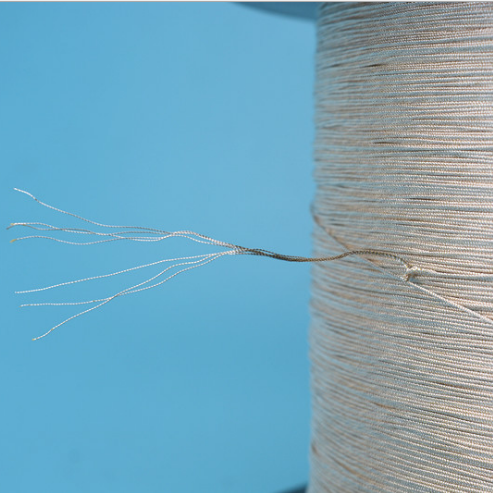

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

Product detail pictures:

Related Product Guide:

Project Ugly Horse: 1989 Ford Mustang LX Photo Gallery | Pure Nickel Cable

Tuesday Briefing: Judges’ Forum, Public Money For Private Schools, NAACP Meeting, Hukill | FlaglerLive | Single Core Copper Cable

Our pursuit and corporation aim should be to "Always satisfy our consumer requirements". We carry on to build and style and design remarkable quality items for both our outdated and new clients and reach a win-win prospect for our clients at the same time as us for OEM/ODM Factory Nylon Taffeta Fabric - High Density Polyethylene (HDPE) – Shielday, The product will supply to all over the world, such as: Qatar, Zimbabwe, Vancouver, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

-

Factory selling Electrical Terminal Crimping Ma...

-

Wholesale Discount Hvac Aluminum Foil Tape - N...

-

Manufacturing Companies for Woven Foil Fabric -...

-

Fixed Competitive Price Static Resistance Wire ...

-

Best Price for Iso 13485 10 Cores Set Wire - ...

-

Manufacturing Companies for 8 Gauge Pvc Coated ...