PriceList for Pearl Braided Tape - High Density Polyethylene (HDPE) – Shielday Detail:

High density polyethylene (HDPE) softening point for 125 ~ 135 ℃,

working temperature 100 ℃;

Material features:

Heat & cold resistance, good abrasion resistance, high tensile strength, electrical insulation, good chemical stability, chemical corrosion resistance; low water absorption and permeability.

Wire by increasing HDPE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various applications:

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

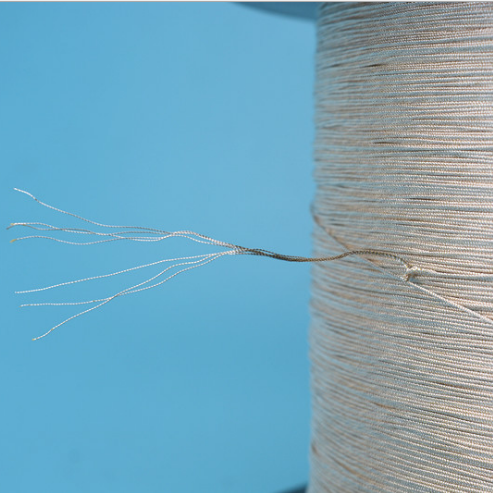

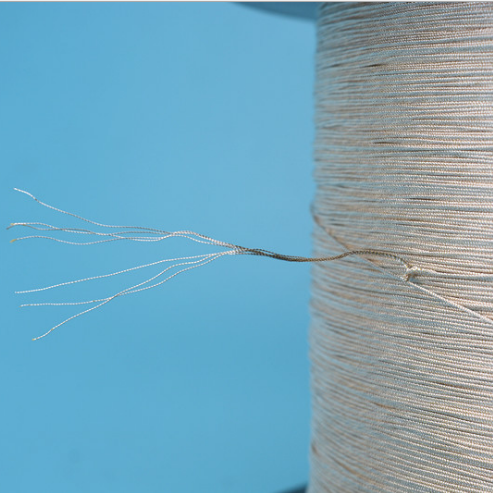

Product detail pictures:

Related Product Guide:

Say Hello to My Little Hands: True (War) Crimes of the Rich and Infamous Filters SVG | High Speed Winding & Braiding Machine

Here’s how Paradise ignored warnings and became a deathtrap | Stainless Steel Braided Sleeve

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for PriceList for Pearl Braided Tape - High Density Polyethylene (HDPE) – Shielday, The product will supply to all over the world, such as: New Orleans, Lahore, Czech Republic, At Present, our products have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

Factory wholesale Usb Electrode Wire - Stainle...

-

High Performance Polyester Anti-static Mesh - ...

-

Factory directly supply Christmas Tinsel Garlan...

-

Discount wholesale Silicone High Quality - Pur...

-

Cheap PriceList for Plastic Coated Steel Wire -...

-

Excellent quality Copper Conductor Silicone - ...