Short Lead Time for High Temp Resistant Tube - High Density Polyethylene (HDPE) – Shielday Detail:

High density polyethylene (HDPE) softening point for 125 ~ 135 ℃,

working temperature 100 ℃;

Material features:

Heat & cold resistance, good abrasion resistance, high tensile strength, electrical insulation, good chemical stability, chemical corrosion resistance; low water absorption and permeability.

Wire by increasing HDPE outer coated layer can improve the flexibility, temperature resistance, chemical resistance and mechanical strength, breakdown voltage. Compared with the ordinary wire, outer coating wire can be insulated , high temp resistant, also the bending life of the wire is significantly improved.

Advantages:

Insulation

High temperature / heating Resistance

Good flexibility

Stress resistance

Resistance against oils

Outer coating material, thickness of coating layer and concrete structure of inner conductive wire can be selected and combined in order to have best performance for various applications:

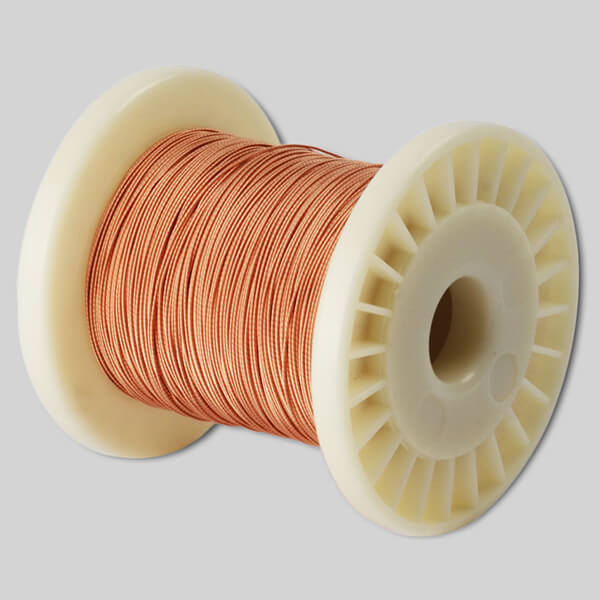

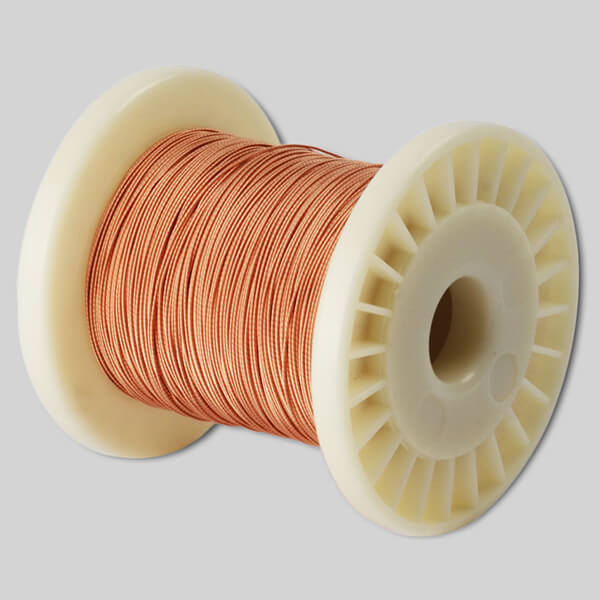

Inner conductive wire material, dia:

Structure: single ,multiple stranded or not stranded / twisting direction, twisting method

1) Singel / stranded wire: Bare copper, tin-plated, silver-plated, gold-plated, nickel-plated, bare copper alloy, tin copper alloy , silver copper alloy, stainless steel etc.

Single wire Dia: 0.01~0.12mm

2) Metallized high strength yarn: above conductive wire covered aramid yarn inside which can bears the vertical tensile strength,be higher strength,more flexible, long life and temp resistance. Yarn Dia: 0.05-0.3mm

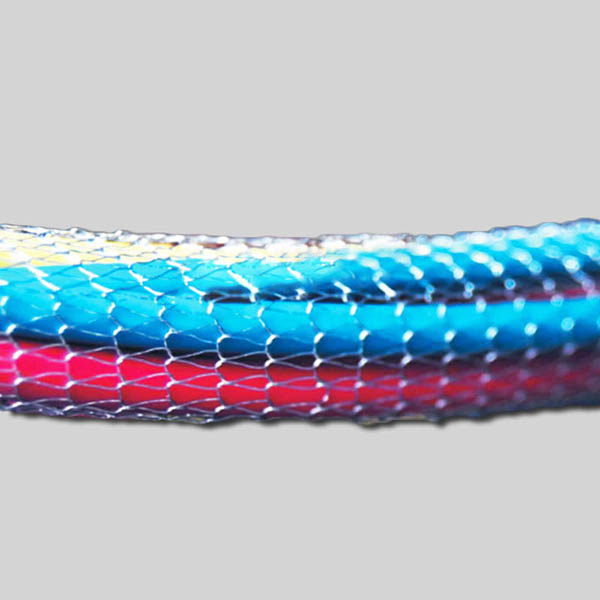

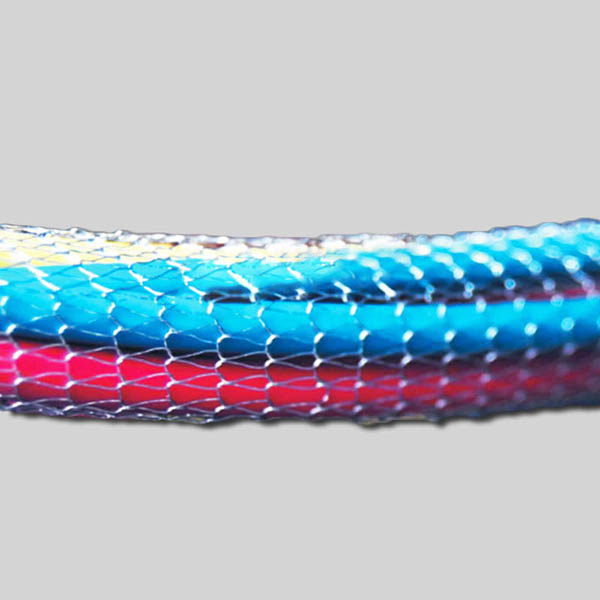

Outer insulation coating: PTFE(Teflon), HDPE(High Density Polyethylene), textile outer etc

Outer Dia: 0.5 – 5.2 mm

Coating layer thickness: ≥0.15 mm

Applications:Smart Textiles ,RFID,Medical ,Heating Etc.

Product detail pictures:

Related Product Guide:

Learning the Art of Mozzarella Making ⋆ Jersey Bites | Single Core Copper Cable

Shilpi Cable: What’s cooking in this smallcap cable company? | Single Core Copper Cable

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Short Lead Time for High Temp Resistant Tube - High Density Polyethylene (HDPE) – Shielday, The product will supply to all over the world, such as: Nigeria, Hamburg, Sacramento, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

-

New Delivery for Metal Fiber Thread - Pure Sil...

-

Reliable Supplier Eye Shadow Shields - Copper ...

-

New Fashion Design for Standard Tarpaulin Sizes...

-

OEM/ODM Supplier Sheet Wholesale Fabric - Meta...

-

Well-designed Sintered Porous Filter - Metalli...

-

Factory made hot-sale Rope Winding Machine - S...